We are an innovative, dynamic and flexible family business.

For over 35 years we offer the development, design and manufacture of fixtures around the electronics manufacturing.

Starting with simple solder masks, the development moved on to titanium carriers and titanium inserts.

Over the years, the company has always evolved and now offers a wide range of fixtures.

In addition, equipment manufacturing found a place in our portfolio (e.g. we manufacture rotary transfer machines for hot caulking of printed circuit boards in plastic housings).

All systems can be produced in single piece production as well as small or large series production. Our employees will be pleased to help you by phone, in video conferences, or directly on site to realize your project in the best possible way.

Quality is the prerequisite for success and competitiveness in the market and at the same time promotes our customer loyalty. We implement this every day in all areas: from development to the support of our customers.

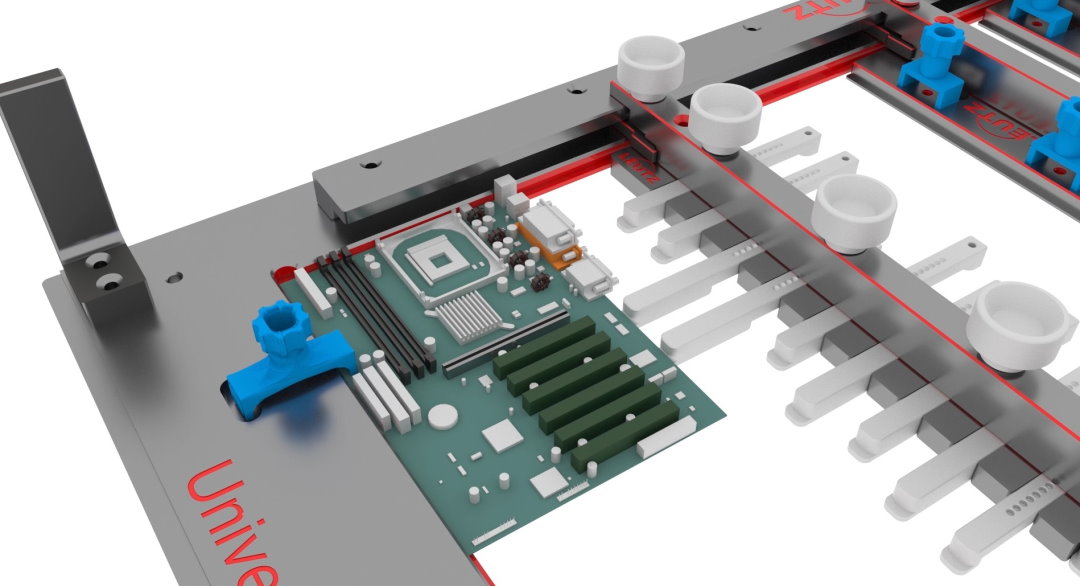

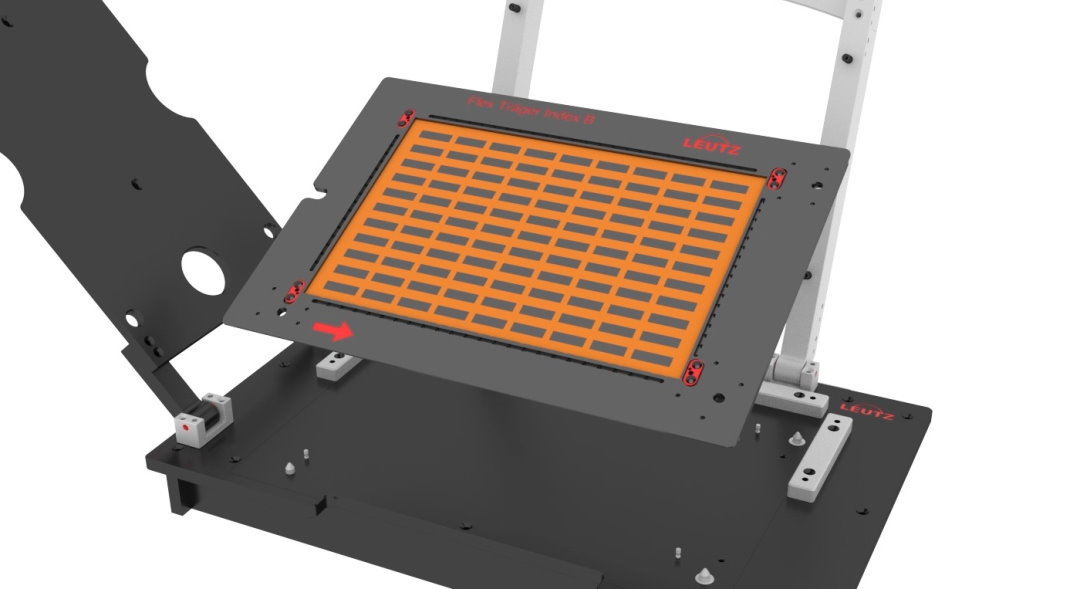

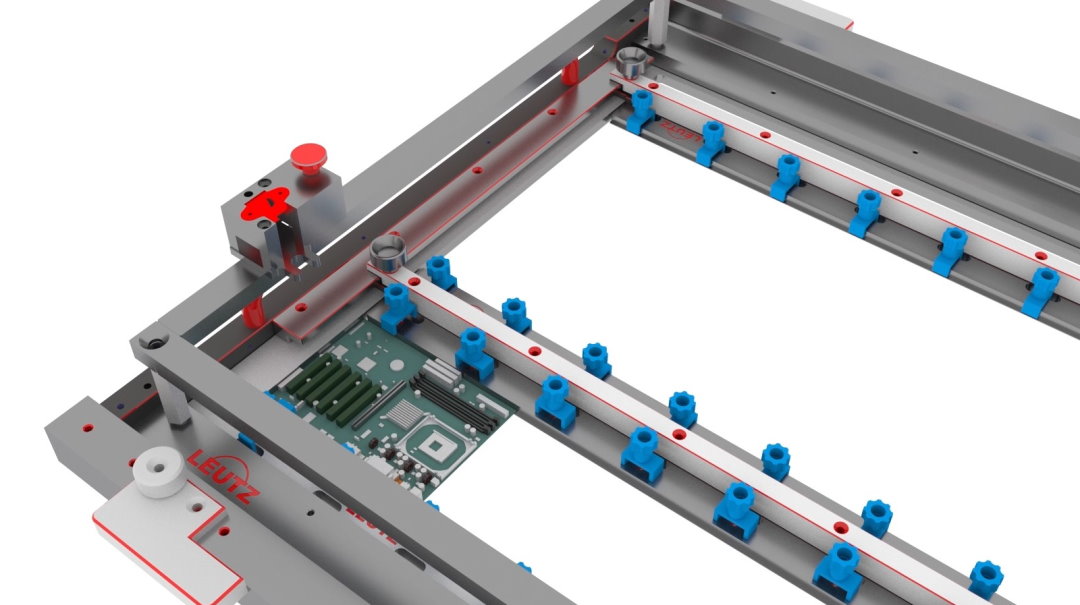

Production of various systems as flexible solutions for soldering systems

Printed circuit boards the standard of electronics manufacturing are in a constant state of change. They are continuously evolving due to miniaturization, component density is increasing and with it the demands on operating equipment. Added to this are trends such as bendable, flexible printed circuit boards, which require innovative solutions.

This is where Leutz Lötsysteme comes into play and offers you suitable process solutions for your respective application.

Our focus areas include:

- Soldering systems

- Workpiece carriers

- Painting carriers

- Separating devices

- Testing fixtures

- Plant engineering

We do not shy away from challenges and tackle new projects with motivation together with our customers.

We also offer various spare parts, solder nozzles, as well as contract manufacturing. Thanks to our experience and the variety of available products, we ensure that our customers receive a coordinated offer.

Research and development is an important area for us. We want to show our customers very good and well thought-out solutions. We can only do this because we are continuously working on our processes and products.

Accompanying services for the success of your series production

The concept, design and quality of the tools and fixtures are decisive for precision, service life, cost-effectiveness and thus the success of the series products. We offer both a broad portfolio of solutions from a single source as well as supporting consulting and other services for your projects.

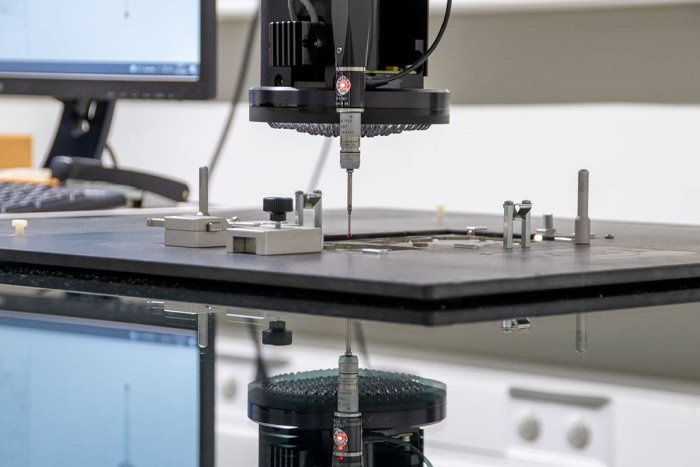

The precision for fixtures in the electronics process significantly influences the quality of the manufactured product. Therefore, in addition to consulting, our range of services also includes the following:

- Tool and mould construction

- Metrology

- Laser technology

- Cleaning for soldering systems

All from one source.

We develop the projects in close consultation with the customer and check every step of production. We have the possibility to measure the accuracy of the parts (incl. protocol). On request, we develop a suitable PokaYoke system for your device. We also offer laser engraving for QR codes, Datamatirx codes and other markings for your products.

We are certified according to DIN EN ISO 9001:2015 and 14001.

News

Dates and new product highlights

Express 48-hour service available on request

If it has to go fast...

We are happy to offer you our express service on request. Within a short time we realize projects from development to production..

Longstanding and reliable partnerships

We have been working successfully with our partners and customers for many years.